Learn about Water Heater Repair

Outline

– Section 1: Why water heater repair matters, how systems work, and the most common warning signs.

– Section 2: Preventive service routines that reduce breakdowns, improve safety, and boost efficiency.

– Section 3: A practical diagnostic path for electric, gas, and heat pump models, with actionable tips.

– Section 4: Costs, parts, and a clear framework for repair versus replacement decisions.

– Section 5: Safety, code essentials, hiring guidance, and a concluding checklist for homeowners.

This outline sets the path from understanding to action. First, you’ll learn how the heater’s core components behave and fail. Next, routine service tasks show how small efforts now avoid large bills later. Diagnostics then help you narrow problems with logic, not guesswork. Finally, a cost lens and safety guidance ground your choices in facts, so you finish with a confident plan.

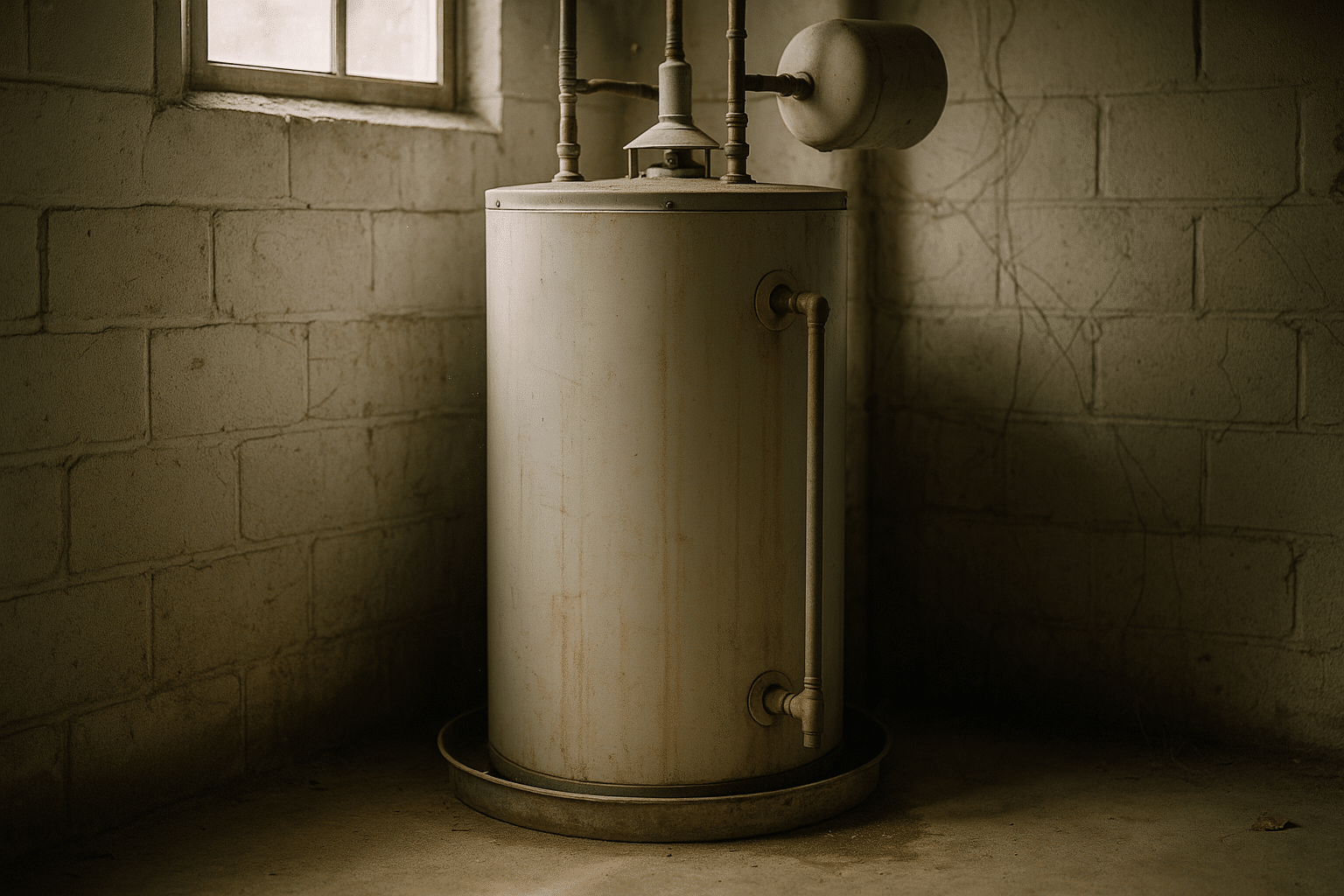

Why Water Heater Repair Matters: Basics, Benefits, and Telltale Symptoms

Water heaters are the quiet workhorses of a home, typically accounting for a notable share of household energy use, often around the mid‑teens to high‑teens percentage. When they falter, comfort drops and costs can rise quickly. Understanding how they work and spotting trouble early turns surprise failures into manageable fixes. Conventional storage tanks warm and hold water at temperature, tankless units heat water on demand, and heat pump models transfer heat from ambient air to water. Each type presents distinct service needs, but the core goals are consistent: safe operation, steady temperature, and efficient energy use.

Common symptoms provide reliable clues. No hot water can point to failed electric heating elements, tripped high‑limit switches, faulty igniters on gas units, or safety lockouts. Lukewarm water may indicate a single failed element in a dual‑element electric tank, a misadjusted thermostat, sediment insulating the bottom of a tank, or a partially restricted burner. Fluctuating temperature can stem from mixing valve issues, scaling, or dip tube deterioration. Discolored or metallic‑tasting water may reflect corrosion, often signaling an anode rod near the end of its life. Popping, rumbling, or kettling sounds frequently come from sediment cooking at the bottom of a tank. Visible leaks might be as minor as a weeping drain valve or as serious as a compromised tank shell.

Address symptoms promptly to protect both the heater and surrounding areas. A small seep can become a major leak that damages floors, drywall, and belongings. If you find active leakage, turn off water at the cold inlet and shut power at the breaker or gas supply before investigating further. Temperature matters too: set around 120°F to limit scald risk and reduce energy waste while still supporting sanitation. Repair isn’t just about stopping the current problem; it’s about restoring stable operation and preventing expensive repeats. Treat your heater like a system tied to water quality, pressure, and ventilation, not an isolated appliance. That mindset helps you fix the root cause, not just the symptom.

– Key early warnings to respect: sudden temperature swings, frequent breaker trips, recurring pilot outages, rust‑tinged water, sulfur odors, and dampness near the base.

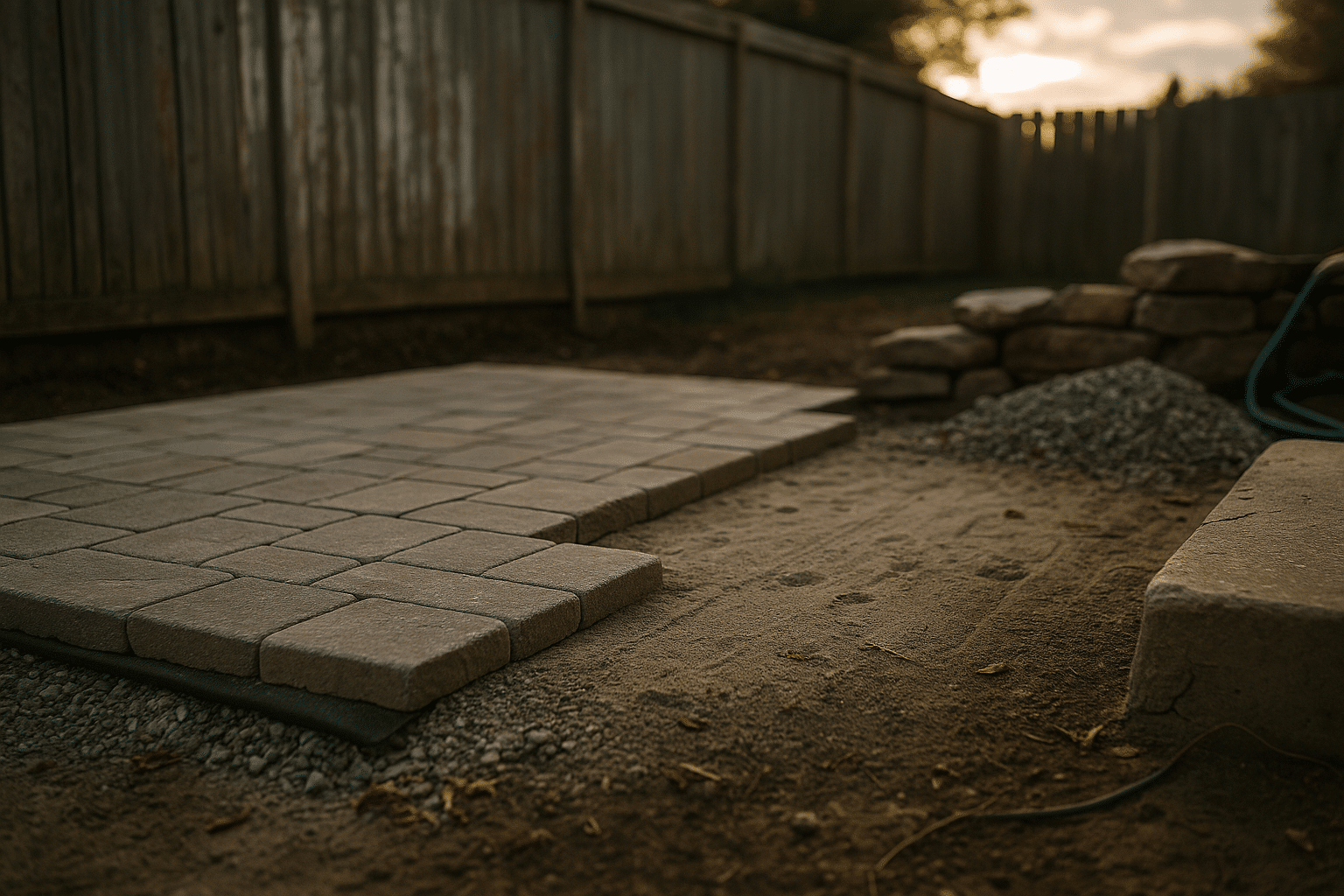

Water Heater Service: Preventive Maintenance That Pays Off

Proactive service can add years to a water heater’s useful life while reducing utility bills and safety risks. Sediment management sits at the center of good care. Minerals drop out of heated water and form a layer of scale and grit inside tanks, muffling heat transfer and stressing components. A controlled flush helps: briefly open the drain valve with the supply off and the pressure relieved, capturing water safely in a bucket or hose to a drain. In hard‑water regions, semiannual flushing is often helpful; in softer water, annual service generally suffices. For tankless units, descaling with manufacturer‑approved procedures keeps heat exchangers efficient and quiet.

The anode rod deserves regular attention. This sacrificial part corrodes by design to protect the steel tank. In average conditions, inspection every two to three years is common, and annually if you use a water softener or have aggressive water chemistry. Replace the rod when it is heavily pitted or reduced to a thin wire. A healthy anode can significantly delay tank corrosion, often making the difference between an early tank failure and a heater that reaches its typical lifespan. Paired with an intact dip tube, it helps keep hot and cold streams properly separated for consistent delivery.

Other service tasks round out a solid program. Test the temperature and pressure relief valve annually by carefully lifting the lever to verify smooth flow and proper reseating; replace the valve if it dribbles or refuses to operate. Confirm water pressure generally stays in the 40–80 psi range; sustained high pressure accelerates wear and may warrant an expansion tank on closed systems. Check the thermostat setting, insulation condition, and, for gas units, that combustion air and venting are unobstructed. For heat pump models, clean air filters and vacuum dust from intake screens, and keep the area clear for airflow. If your unit sits in a space where leaks could cause damage, a pan with a drain line and a moisture alarm provide inexpensive peace of mind.

– Quick service checklist: annual flush, anode inspection on schedule, T&P valve test, thermostat at about 120°F, pressure check, drain pan and alarm verification, and venting/airflow inspection.

These simple habits can reduce fuel use, quiet noise, stabilize temperatures, and catch problems while parts are still inexpensive. Preventive service is not glamorous, but it rewards you with reliable showers, lower bills, and fewer weekend emergencies.

Hot Water Heater Repair Diagnostics: Step‑by‑Step for Electric, Gas, and Heat Pump Units

Diagnosis works best when it is systematic. Start with safety: shut off power at the breaker for electric units (they commonly run at 240 volts) and close the gas valve or set the control to off for gas models. Turn off the cold water supply if you see active leaking. With basics secure, move from the simple to the complex, verifying each assumption before replacing parts.

For electric tanks, a tripped breaker or a popped high‑limit switch on the upper thermostat can explain a sudden loss of hot water. Reset once and observe; repeated trips signal a deeper issue like a shorted element or faulty thermostat. Use a multimeter with the power off to check element resistance; a reading near infinity suggests an open element, while near zero can indicate a short. Lukewarm water often points to a failed lower element because the upper typically heats first and satisfies the control. Scale can also blanket elements, creating hot spots and shortened life. Inspect wiring connections for discoloration or looseness, and confirm the dip tube is intact to prevent cold water from mixing at the outlet.

For gas storage units, verify the pilot or igniter. If the pilot will not stay lit, a weak thermocouple or flame sensor often sits at fault, though poor combustion air or downdrafts can also play a role. Check for proper vent rise and clearances, and listen for whooshing or chuffing that hints at restricted airflow. If ignition has gone electronic, confirm that the igniter glows or sparks and that safety interlocks are satisfied. Intermittent heating may stem from a failing gas control valve, partially clogged burner ports, or excessive scale causing overheating near the bottom of the tank.

Heat pump water heaters bring different checks. Ensure ambient temperature is within the operating window and that filters and coils are clean. If recovery is slow, the unit may be running in heat pump mode alone; selecting hybrid or high‑demand settings temporarily can help during peak usage. Drain condensate lines, clear kinks, and inspect for icing in cool, humid spaces.

– Red flags to stop and call a licensed pro: the smell of gas, scorch marks, persistent tripping of safety devices, evidence of backdrafting, and any uncertainty around electrical testing.

A calm, ordered approach minimizes parts cannon repairs and shortens downtime. By confirming power, fuel, controls, and water flow in sequence, you isolate the fault and choose a fix that solves the problem without creating new ones.

Costs, Parts, and the Repair‑or‑Replace Decision

Budget decisions benefit from realistic ranges and a simple framework. Routine flushing service may fall in a modest range depending on region and access. Replacing a temperature and pressure relief valve is typically a straightforward job with a moderate parts cost. Electric heating elements and thermostats tend to be relatively affordable, with total repair prices influenced by labor rates and whether the tank has seized components from age or scale. Gas components like igniters, thermocouples, flame sensors, and gas valves often range higher, especially if venting evaluation or combustion tuning is included.

Representative ballpark figures, which vary by location, brand, capacity, and installation complexity, can help you plan: anode rod replacement might land between a low few hundred dollars to the mid‑hundreds including labor, electric element and thermostat work can run in a similar neighborhood, ignition repairs are often mid‑hundreds, and T&P valve swaps typically sit on the lower end of that span. Full replacement for a standard storage tank frequently falls somewhere in the low four figures depending on size, venting type, and permit needs. Tankless replacement often costs more upfront due to venting and gas line sizing, while heat pump units can carry higher equipment prices but offer notable efficiency gains that may be offset by incentives where available.

To choose wisely, apply a clear rule of thumb. If a repair exceeds roughly half the cost of replacement and the unit is beyond two‑thirds of its expected service life, replacement often yields better long‑term value. Also factor projected energy savings: newer units with higher efficiency ratings can trim annual costs, sometimes on the order of many tens to low hundreds of dollars, depending on usage patterns and local rates. Spread that benefit over the heater’s lifespan, and a higher initial price can look more reasonable. Consider hidden costs too: recurring leaks, hard‑to‑find parts, or inadequate hot water during peak times all carry value hits that do not show on a repair invoice.

– Decision checklist: confirm age and type, price the specific repair, compare to full replacement including permits, estimate annual energy savings, weigh reliability history, and account for household hot water demand growth.

A transparent look at both the near‑term bill and the long‑term operating picture prevents regret. Use actual quotes, not guesses, and keep notes on past service so your decision is grounded in experience, not just today’s problem.

Safety, Codes, and Hiring Pros: What to Expect and What to Do Next

Water heaters touch electricity, gas, scald risk, and pressure—four reasons safety deserves center stage. Basic protections start with a correctly sized and unobstructed temperature and pressure relief valve that discharges to a safe location, typically ending near the floor without threads or caps. In many areas, storage tanks require seismic strapping, a drain pan with a routed drain line when damage risk exists, and proper clearances from combustibles. Gas models benefit from a sediment trap on the gas line, confirmed draft or condensate management, and correct vent slope and terminations. Electric models should have secure wiring, intact covers, and no signs of overheating at lugs or thermostats. All heaters appreciate stable water pressure and thermal expansion control on closed systems.

Permits and inspections are more than bureaucracy; they are quality and safety checks. Local codes vary, but expect verification of venting, combustion air, drain pan placement, discharge piping, temperature settings, and relief valve accessibility. Documentation can help with insurance and resale value, showing that the installation met contemporary standards. If your unit lives in a tight closet, remember that adequate airflow and service access are not optional—a cramped space that looks tidy may be unsafe or unserviceable.

When hiring, look for licensing, insurance, and a track record with your specific heater type. Ask how diagnosis will be performed, what tests will be documented, and which parts are typically stocked on the truck. Request a written scope of work that lists materials, any disposal fees, permit handling, and warranty terms. Clarify whether pricing is flat rate or time and materials. A clear process reduces surprises, and a well‑run visit often includes verifying thermostat settings, checking for leaks at connections, testing the relief valve, inspecting the anode condition where accessible, and confirming combustion or electrical safety.

– Before the service call: note symptoms and when they occur, photograph error codes or leaks, clear a path to the heater, and locate shutoffs. After the visit: record what was done, keep receipts, and set a reminder for the next maintenance milestone.

Conclusion and next steps: Treat your water heater as a system you can steward confidently. Schedule routine service, track key data like age, pressure, and temperature, and respond quickly to new sounds, smells, or moisture. With a practical maintenance rhythm and a sensible repair‑or‑replace framework, you protect comfort, lower risk, and spend wisely. The result is simple: fewer cold‑shower surprises and a reliable supply of hot water when you need it most.