Learn about Tile Installation

Outline

The article follows a practical path from planning to long-term care:

– Why tile installation matters and what success looks like

– Planning and materials: tile types, substrates, and layout logic

– Floor tile installation: step-by-step workflow and on-site tips

– Tile installation service: how to evaluate estimates and pros

– Conclusion and care: maintenance, repairs, and lifetime value

Why Tile Installation Matters: Durability, Safety, and Everyday Ease

Tile installation is more than setting squares in a grid; it is a system where structure, mortar chemistry, grout composition, and layout precision work together. When the system is well designed and executed, the payoff is real: floors that handle daily foot traffic, splashes, pet claws, and chair legs with grace. Properly installed tile is known for impressive longevity—often measured in decades—because it resists moisture, sun exposure through windows, and abrasion better than many finishes. It also supports indoor air quality by presenting a surface that does not harbor dust and is easy to clean without harsh chemicals. In kitchens, baths, entryways, and mudrooms, tile’s water resistance and dimensional stability shine, provided the underlying layers are planned and installed correctly.

The stakes are higher than aesthetics. Substrate flatness and movement control affect safety and performance. Lippage—uneven tile edges from poor leveling—creates trip hazards and shadows that exaggerate flaws. Moisture trapped beneath the assembly can lead to debonding or mold in adjacent materials. Thoughtful detailing, such as perimeter movement joints and soft joints at changes of plane, lets the surface expand and contract with seasonal shifts without cracking. Slip resistance matters, too. Tiles with a surface texture and adequate dynamic coefficient of friction improve footing in wet zones, while larger-format tiles reduce grout lines and can make cleaning faster, though they demand tighter flatness tolerances during prep.

Financially, quality tile work can be cost-effective over the long haul. While initial costs may exceed some alternatives, life-cycle math often favors tile because it performs for years with minimal maintenance. For homeowners balancing budgets, comparing total ownership costs—materials, labor, cleaning, and potential replacement—helps frame a rational decision. In short, tile rewards good planning: choose appropriate materials, prepare the substrate, follow a sound installation approach, and routine care becomes straightforward, leaving you with a surface that looks composed and feels solid underfoot.

Planning and Materials: Tile Types, Substrates, and Layout Logic

Every successful tile installation starts on paper. Begin by defining location, expected wear, moisture exposure, and cleaning expectations. From there, select tile materials suited to the environment. Ceramic is versatile for walls and light to moderate floor traffic. Porcelain, with water absorption typically below 0.5%, handles exterior freeze-thaw zones and wet interiors with confidence. Natural stone—marble, travertine, granite, slate—adds distinctive character and varies widely in hardness and porosity, requiring sealed maintenance. Glass and mosaic tiles create visual accents and conform well to curves but may require specialized mortars and careful handling to prevent visible trowel lines or substrate shading.

Surface texture and slip resistance matter in kitchens, entries, and baths. A lightly textured matte finish often balances cleaning ease with traction. For areas subject to frequent moisture, check the product’s slip-related specifications and choose a finish designed for wet conditions. Tile sizing influences both aesthetics and install difficulty. Large-format tiles (one edge ≥ 15 inches) minimize grout lines and can make small rooms appear larger, yet they demand a flatter substrate. Rectified tiles, cut to precise dimensions, allow narrow joints but amplify layout accuracy requirements. Pressed tiles are slightly rounded at edges and often more forgiving for DIYers.

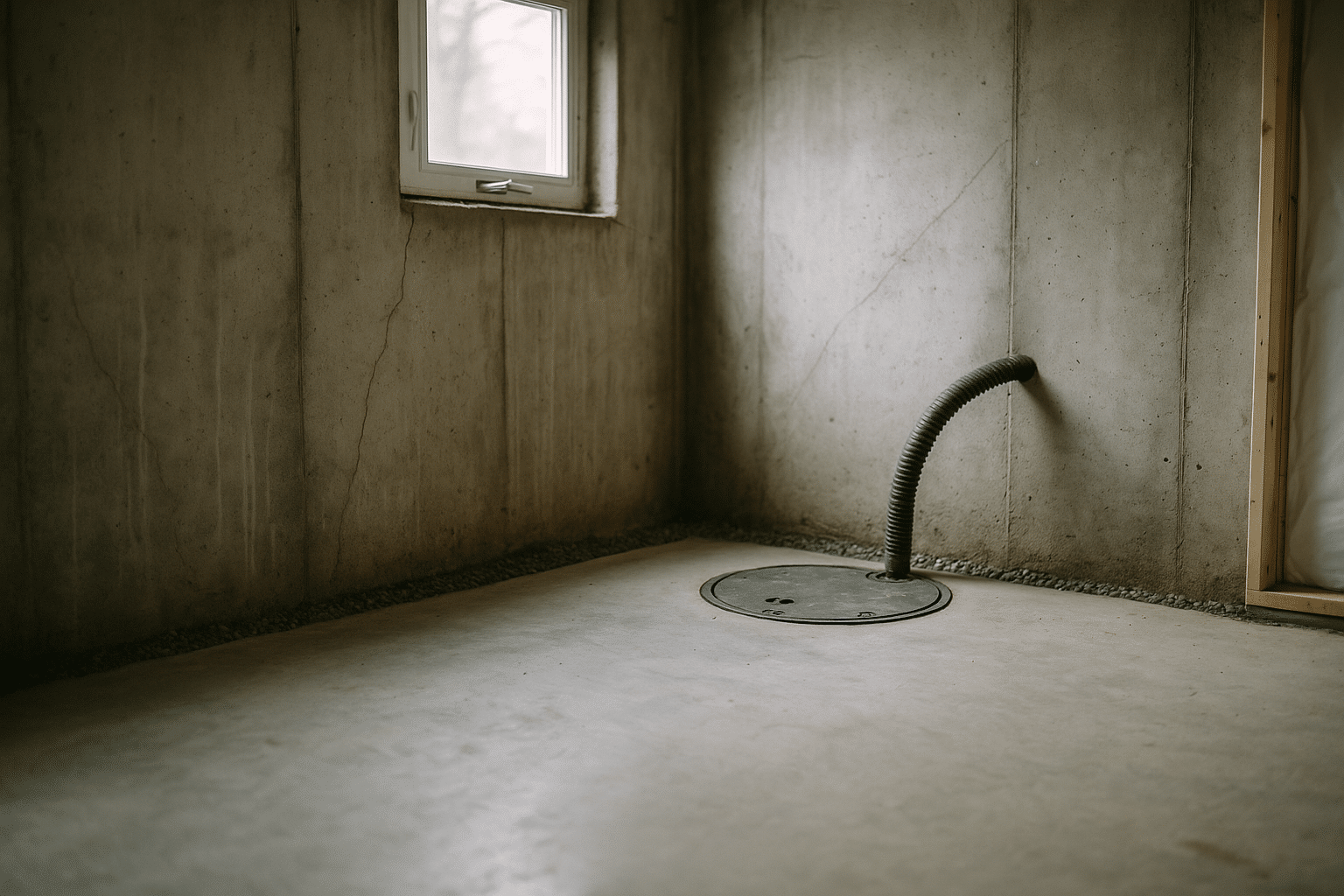

Substrate readiness is the backbone. Concrete slabs must be clean, sound, and within flatness tolerances; hairline shrinkage cracks may be treated with membranes designed for crack isolation. Over wood framing, create a suitable base (for example, a tile underlayment board or an uncoupling membrane) after verifying deflection criteria and fastening schedules. Moisture-prone zones benefit from waterproofing membranes that turn showers, tub surrounds, and bath floors into controlled systems rather than hopeful guesses. Adhesives and grouts should align with tile type and service conditions. Polymer-modified mortars increase bond strength and flexibility, especially for porcelain and large-format panels. Grout choices include cementitious (cost-effective, sealable), epoxy (high stain resistance, chemical durability), and ready-mix hybrid options that balance color consistency with easy cleanup.

Good planning includes smart allowances and waste factors. Order 10–15% extra tile to cover cuts, breakage, and future repairs; patterned layouts or diagonal designs may need a bit more. Map the room with a centerline layout to balance cuts on opposing walls and avoid slivers at thresholds. Dry-lay a few rows to test pattern rhythm and joint alignment across doorways and transitions. Consider these quick planning checks:

– Confirm transitions to adjacent floors to prevent trip edges

– Verify door clearances and baseboard heights

– Identify locations for movement joints in larger areas

– Choose grout joint width that suits the tile’s size and facial variation

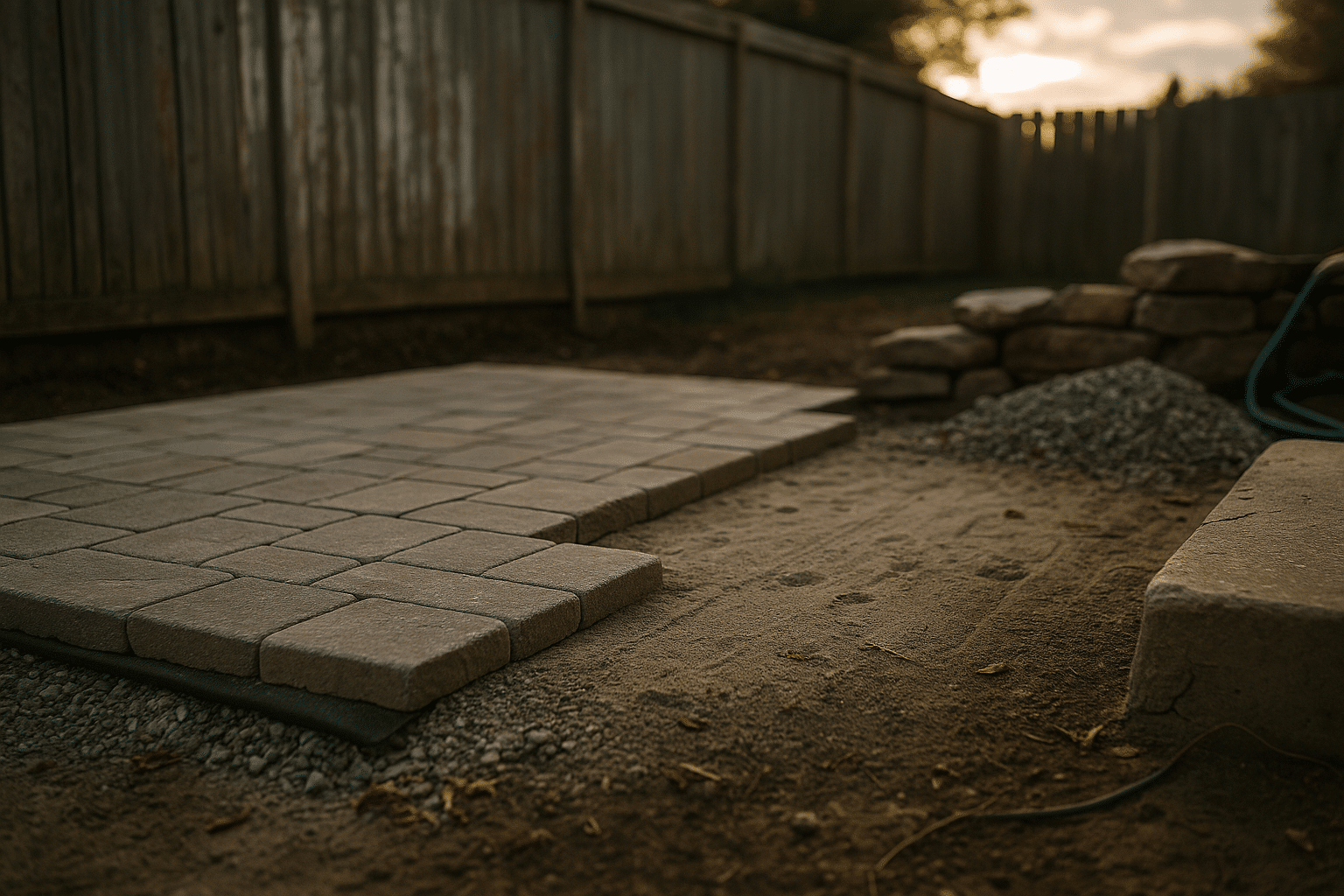

Floor Tile Installation: A Step-by-Step Field Guide

Great floor tile installation follows a dependable sequence: assess, prepare, set, grout, and protect. Start by evaluating the substrate. For small to medium tiles, many installers aim for flatness within about 1/4 inch in 10 feet; for large-format, a tighter target around 1/8 inch in 10 feet helps limit lippage. Grind high spots and fill low areas with patching compounds compatible with the chosen mortar. Clean thoroughly—dust, paint overspray, and old adhesives undermine bond strength. In moisture-sensitive areas, apply a waterproofing or crack-isolation membrane according to the manufacturer’s coverage rates and cure times.

Gather the right tools before mixing mortar:

– Notched trowels sized to tile format (for example, 1/4 x 3/8 inch for many floor tiles)

– Margin trowel and mixing paddle for consistent mortar blend

– Tile spacers and level or straightedge for alignment checks

– Rubber mallet and beating block to seat tiles evenly

– Tile cutter and wet saw for clean, accurate cuts

– Buckets, sponges, and microfiber cloths for cleanup

Mix thin-set mortar to a creamy consistency, let it slake if required, then remix. Comb in straight, parallel ridges; directional troweling helps the ridges collapse efficiently when the tile is pressed and moved slightly perpendicular to the ridges. Back-butter larger tiles to improve coverage. Aim for at least 80% mortar coverage in dry areas and near full coverage in wet zones; lift a test tile occasionally to confirm. Use spacers to maintain consistent joints, checking rows with a straightedge to control lippage. Maintain movement joints at perimeters and through larger fields to accommodate thermal and structural shifts.

After tiles set (often 24 hours for light foot traffic, depending on temperature and mortar), proceed to grouting. Pack joints fully, working diagonally across lines. Clean the surface in stages, using minimal water to prevent grout washout and efflorescence. Once cured, seal cementitious grout if recommended; epoxy grouts typically do not need sealing. Finish with flexible sealant at changes of plane and along edges where tile meets dissimilar materials. Protect the new surface with breathable coverings if other trades will work nearby. Common pitfalls include rushing layout, ignoring flatness, skipping movement joints, and mixing mortar in inconsistent batches. Patience, steady pacing, and frequent quality checks are the quiet secrets behind floors that look refined and feel solid.

Tile Installation Service: How to Compare Pros, Estimates, and Contracts

Hiring a tile installation service can compress timelines, reduce risk, and deliver a refined finish. Begin by shortlisting firms with verifiable experience in the project type you need—bath remodels, heated floors, exterior patios, or large-format porcelain panels each require distinct skills. Ask for a portfolio of similar work and recent references you can call. Industry-recognized training and certification signal commitment to methods aligned with current standards. Insurance and appropriate licensing protect both parties and should be easy to document.

Request detailed, written estimates that break down scope and quantities. A transparent proposal typically includes:

– Square footage and layout pattern (straight, staggered, herringbone)

– Surface prep steps, including flattening targets and membrane types

– Tile, mortar, grout, and trim profiles with product categories

– Movement joint strategy and perimeter details

– Timeline with milestones, cure periods, and access limits

– Cleanup, disposal, and protection of adjacent finishes

Discuss pricing structure openly. Labor rates vary by region and complexity, but many floor projects in the United States fall within a broad range such as $8–$25 per square foot for labor, with tile material spanning from budget-friendly to premium. Underlayments, waterproofing, heating mats, decorative trims, and complex cuts add cost; so do awkward room geometries and tight timelines. A thoughtful pro will explain where your money is going and how to prioritize upgrades for value—improving substrate flatness, for example, often has a bigger impact on results than a small tile upgrade.

Clarify change-order procedures and warranty terms. Written change orders prevent misunderstandings if surprises appear behind old finishes. Warranties commonly cover workmanship for a defined period; they typically exclude issues from structural movement or water events beyond the tiled area. Expect the contractor to outline dust control (using vacuums with fine filtration), noise windows, and daily cleanup. Safety matters, too: cutting practices that manage silica dust and personal protective equipment policies indicate a professional culture. Red flags include vague scopes, reluctance to provide references, and requests for large upfront payments without a clear schedule. A well-chosen installer turns a complex craft into a calm, predictable process—and that peace of mind often pays for itself.

Conclusion and Care: Maintenance, Minor Repairs, and Long-Term Value

Once your tile is down and grouted, the long game begins—simple routines that keep surfaces looking fresh and performing reliably. Sweep or vacuum grit that can act like sandpaper, then damp-mop with a pH-neutral cleaner. Avoid oil soaps or harsh acids that can dull finishes or degrade cementitious grout. Door mats at entries catch debris before it reaches the floor, and felt pads under furniture help prevent abrasion. In wet rooms, good ventilation reduces condensation that feeds mildew on grout lines. Sealing cementitious grout as recommended boosts stain resistance; natural stone may need periodic sealing as well, depending on porosity and traffic.

When issues appear, address root causes instead of symptoms. A single cracked tile might trace back to a point load, a void in mortar coverage, or movement in the substrate. If a hollow-sounding tile is localized, a careful removal and replacement is often feasible without disturbing the field. Color-matched flexible sealant should replace rigid grout at changes of plane—corners, counters, and tub edges—where movement concentrates. Efflorescence, a white crystalline deposit, signals vapor migration; reducing moisture exposure and gentle cleaning usually help. For persistent discoloration from spills, epoxy grout provides notable stain resistance on future projects, though it involves a more precise installation process.

As you plan for the years ahead, think in terms of total ownership. Tile has a reputation for durability, and when combined with proper substrate design and thoughtful detailing, it can deliver decades of service. Heated floors integrate well with many assemblies, enhancing comfort without sacrificing performance, so long as temperature limits and movement provisions are respected. If you anticipate heavy rolling loads, consider smaller tiles or mosaics that distribute stress through more grout lines. A periodic checklist keeps things predictable:

– Quarterly: inspect caulked joints, touch up where needed

– Biannually: deep-clean grout and reseal if recommended

– Annually: check for cracked or loose tiles and address promptly

– As needed: replace damaged base or trim pieces to maintain a water-tight perimeter

For homeowners weighing DIY against hiring a tile installation service, the calculus balances time, tools, and risk. A professional brings pattern layout insight, substrate correction skills, and pacing that avoids common pitfalls. DIYers can succeed by starting with smaller, simpler rooms and by respecting prep and cure times. Either path benefits from careful planning and realistic scheduling. With the right materials, methodical execution, and light but consistent maintenance, your tile floor becomes more than a hard surface—it becomes the quiet, resilient stage for daily life.