Learn about Roofing Replacement

Outline:

– Section 1: Repair or Replace? Reading the Signs and Doing the Math

– Section 2: What Happens in a Roof Replacement: From Tear-Off to Final Nail

– Section 3: Roof Repair Services: Targeted Fixes that Extend Roof Life

– Section 4: New Roofing for a House: Designing for Today and Decades Ahead

– Section 5: Hiring, Contracts, Permits, and Aftercare: Set Yourself Up for Smooth Roofing

Repair or Replace? Reading the Signs and Doing the Math

Your roof is a working system, not just a layer of shingles, shakes, metal, or tile. It manages sun, wind, rain, and temperature swings day after day, so wear is inevitable. The first decision most homeowners face is whether a targeted repair can safely extend service life or whether a full replacement is the more responsible investment. Start by assessing age and material: common asphalt shingles often last 15–30 years, standing-seam metal 40–70, concrete or clay tile 50+, and slate 75–100+ when well maintained. Geography matters; coastal salt air, high UV in sunny climates, frequent hail, or freeze–thaw cycles can shorten those ranges.

Visual clues tell you a lot. Curled or cupped shingles, widespread granule loss (look in gutters), brittle or cracked tiles, loose ridge caps, sagging sheathing, and daylight visible in the attic indicate systemic issues. Chronic leaks around penetrations—chimneys, skylights, vents—often point to failing flashing rather than a failed field surface, which is a common target for repair. Moldy roof decking in the attic signals ventilation or moisture problems that won’t be solved by a quick patch. If more than one roofing square out of every five shows moderate damage, odds tilt toward replacement.

Cost-benefit thinking helps. A frequently used rule of thumb: if the roof has consumed 80% or more of its expected life and the repair quote approaches 20–30% of a full replacement, consider replacing. Why? You pay twice for access and setup, and piecemeal fixes on an aging system can cascade. Conversely, a 7-year-old roof with isolated wind damage is usually a strong candidate for repair, especially if underlayment and decking remain sound. Typical full replacement on a mid-size home in many U.S. markets ranges roughly from the low five figures upward depending on material, slope, story count, and details; well-scoped repairs can be a fraction of that.

To decide confidently, build a simple matrix:

– Age vs. expected lifespan

– Percentage of surface with damage

– Source of water entry (field vs. flashing)

– Attic condition: insulation dryness, wood staining, daylight

– Local climate risks for the next 10–15 years

When those factors converge on high risk and high recurring repair cost, replacement often becomes a measured, not dramatic, choice. When they point to confined issues and otherwise healthy materials, a skillful repair can give you years more value.

What Happens in a Roof Replacement: From Tear-Off to Final Nail

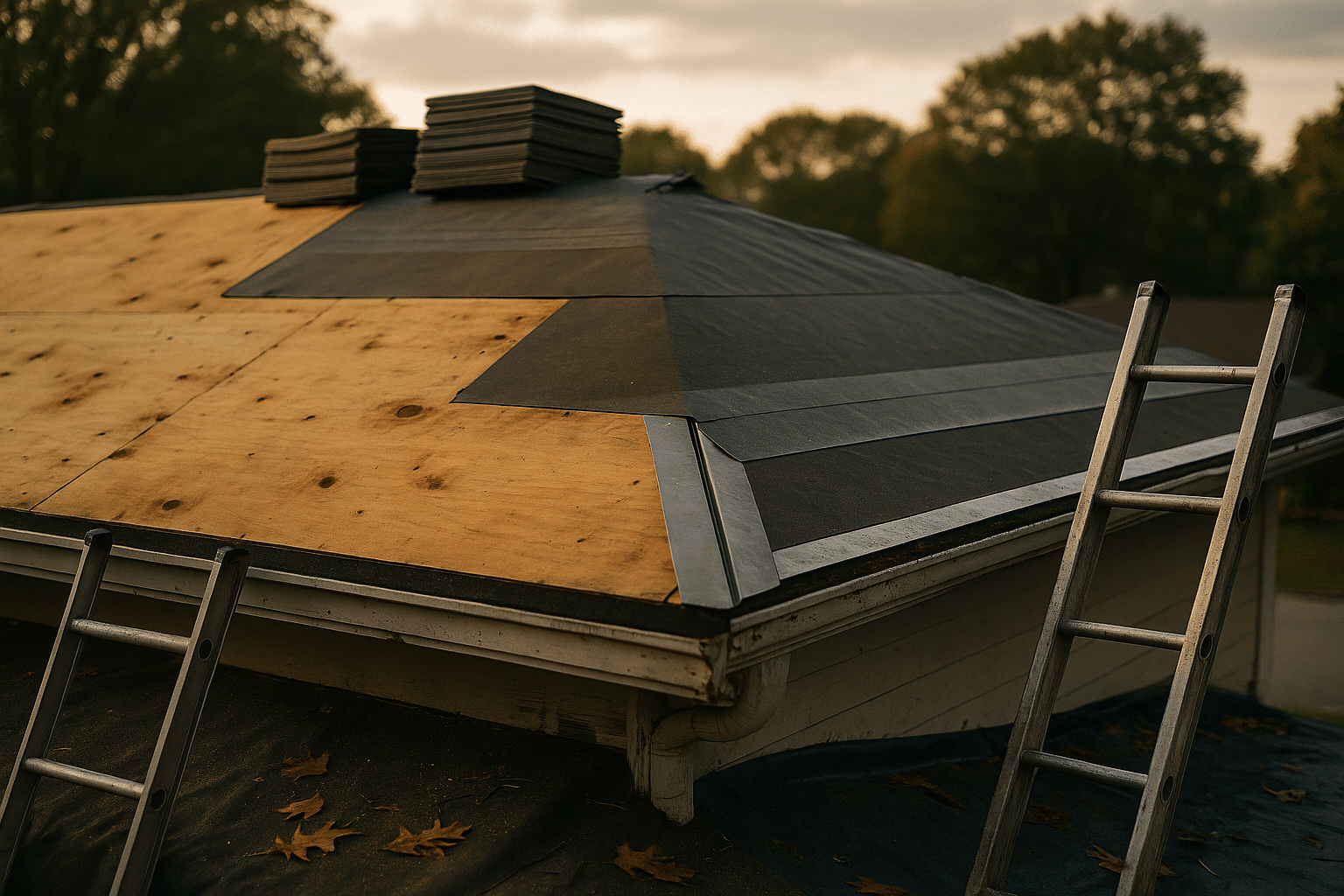

A full replacement is a coordinated sequence designed to protect your home from the rafters up. It usually begins with site preparation: crews cover landscaping, set up safety lines, and place a dumpster for debris. Tear-off removes the existing surface down to the deck, which reveals the truth about the structure. Soft or delaminated sheathing is replaced, often by the sheet with transparent per-sheet pricing in your contract. At the eaves and valleys, self-adhering ice and water barrier is applied in cold or mixed climates to defend against ice dams and wind-driven rain. A synthetic or felt underlayment blankets the remainder, serving as a secondary water shed.

Edges and joints are critical. Drip edge at eaves and rakes directs water into gutters and preserves the deck from capillary action. Flashings—step, counter, and apron—bridge transitions at walls, chimneys, and dormers. Penetrations such as plumbing stacks receive boots rated for UV and temperature swings. Balanced ventilation is set up with continuous soffit intake and a ridge outlet when the design allows; this reduces heat buildup, moderates moisture, and can extend shingle or coating life. Only then is the visible surface installed: starter courses at eaves, field courses aligned to manufacturer guidelines, careful treatment of valleys (open metal or woven, depending on the spec), and properly fastened ridge caps.

Timeframes depend on weather, complexity, and crew size. A straightforward, one-story gable roof might be completed within a couple of days in fair conditions, while a steep, cut-up roof with multiple valleys or a heavy material like tile can take a week or more. Cost drivers include pitch, height, access, disposal weight, material class, and regional labor. Expect disposal and logistics to account for a noticeable share of the bill, and ask that recycling of asphalt shingles or metal be pursued where facilities exist.

To compare quotes fairly, look for line-item clarity:

– Tear-off scope (number of layers)

– Underlayment type and ice barrier coverage

– Flashing metals and replacement vs. reuse

– Ventilation components and net free area targets

– Decking replacement allowance per sheet

– Fastener type and installation pattern

– Cleanup, magnetic nail sweep, and final inspection

When the final nail is driven, a conscientious contractor performs a walkthrough, photographs critical details, and explains care and warranty terms. That documentation is valuable for insurance records and future resale.

Roof Repair Services: Targeted Fixes that Extend Roof Life

Repair services shine when problems are isolated and the rest of the system is in good shape. Common culprits include deteriorated flashing at chimneys and sidewalls, cracked pipe boots, missing or lifted shingles after a wind event, and leaks traced to skylight curbs. Nail pops create tiny water paths that stain ceilings months later. In tile systems, a slipped or broken tile may expose underlayment that was never intended to see years of sun. Metal roofs can develop minor seam separation or failed sealant at penetrations, which are often addressable without disturbing large areas.

A thorough repair begins with tracing water intrusion to its source. Pros lift surrounding courses carefully, check fasteners, and inspect the deck for darkened or softened wood. Flashing is replaced rather than endlessly resealed when aging or corroded. New shingles or panels are woven or locked to blend with the field, aiming for both function and a tidy appearance. Vent boots are swapped for upgraded versions designed to tolerate UV and movement. Sealants are used as a belt-and-suspenders measure, not as the only line of defense.

Costs vary with access, height, and materials. Many companies charge a service-call fee that covers diagnostic time, with simple fixes landing in the low hundreds and more involved repairs—chimney re-flashing, valley rebuilds, partial underlayment replacement—running higher. Emergency tarping to stabilize a leak during a storm is typically a separate fee, worthwhile to prevent interior damage. If wind or hail triggered the issue, detailed photos, date-stamped invoices, and moisture readings help when speaking with your insurer.

Homeowners can reduce surprises by adopting a light maintenance routine:

– Clear leaves and grit from valleys and gutters each season

– Trim branches that scuff surfaces or drop heavy debris

– Scan the attic after major storms for damp insulation or staining

– Look for granular piles at downspouts that indicate surface wear

– Watch ceiling corners and around skylights for early signs of moisture

Know the limits of a patch. If you are chasing the same leak twice in a year, or if multiple planes show damage, it is time to revisit the repair-vs-replace decision. Effective repairs buy time and protect interiors; they are not meant to prop up a system that has broadly reached the end of its service life.

New Roofing for a House: Designing for Today and Decades Ahead

Starting from scratch on a new house—or replacing with a design mindset—opens opportunities to match materials, performance, and aesthetics to your climate and goals. Think of the roof as an energy and durability strategy as much as a look. Material choices each bring trade-offs. Architectural asphalt is widely used for value and versatility. Standing-seam metal offers long service life, lower maintenance, and strong wind resistance, with profiles that complement modern and farmhouse styles. Concrete or clay tile delivers thermal mass and distinctive texture but requires framing that can handle added weight. Natural slate is durable and striking where budgets and structure allow. Engineered composites aim for classic looks with moderate weight and impact resistance.

Climate fit comes first. In wildfire-prone areas, prioritize assemblies with high fire ratings and ember-resistant venting. Along coasts and open plains, wind uplift resistance and corrosion protection matter. Hail-prone regions benefit from impact-rated surfaces that can reduce the frequency of replacements. Snow country calls for robust underlayment at eaves, adequate ventilation to limit melt-and-freeze cycles, and details like snow guards on slick surfaces to protect entries and landscaping.

Energy performance and comfort are close seconds. Lighter, reflective colors in hot zones can reduce heat gain and help trim cooling loads. Good attic ventilation paired with appropriate insulation levels stabilizes indoor temperatures and protects the roof deck from moisture. In many homes, a well-detailed continuous ridge vent and balanced soffit intake manage airflow quietly and effectively. If solar is on your horizon, plan attachment points and conduit runs now; a clean rectangle of south or west roof with minimal obstructions keeps future options open and avoids rework.

Design touches complete the picture. Coordinated metal accents—gutters, valleys, and flashing—can enhance curb appeal when chosen thoughtfully. Color matters more than many expect; darker shades read refined but run warmer, while mid-tones strike a balance. Ask to see large samples in outdoor light before deciding. Budget-wise, account for underlayment upgrades, ventilation components, flashing metals, and contingencies for deck repair so you are not squeezed late in the project.

For quick alignment, match goals to features:

– Hot climates: reflective surfaces, generous intake and ridge ventilation

– Cold climates: ice barrier at eaves, air sealing below, balanced venting

– Windy zones: higher-rated fastener patterns and interlocking profiles

– Hail regions: impact-resistant classifications and solid deck attachment

– Coastal areas: corrosion-resistant metals and sealants

A roof chosen with these factors in mind will protect quietly, look composed, and support long-term plans without constant attention.

Hiring, Contracts, Permits, and Aftercare: Set Yourself Up for Smooth Roofing

Choosing who builds your roof is as important as what goes on it. Start with credentials you can verify: local licensing where required, general liability and workers’ compensation coverage, and a record of completed projects in your area. Ask who will be on the roof—company crews, subcontractors, or a mix—and how supervision works. Communication style matters; clear explanations and timely updates often indicate a disciplined operation behind the scenes.

Request written, comparable estimates. The simplest way to compare apples to apples is to insist on detail. Strong proposals spell out tear-off layers, underlayment type and ice barrier coverage, flashing metals and whether they will be replaced or reused, ventilation strategy with target net free area, deck repair pricing per sheet, and cleanup commitments. Payment schedules should be tied to milestones, not just dates, with a modest deposit and the bulk due upon substantial completion and punch-list resolution. Clarify how change orders are handled and what triggers them.

Permits and inspections protect you. Many jurisdictions require permits for reroofing, especially when structural or ventilation changes are planned. Coordinated inspections—sometimes mid-project to confirm underlayment and flashing, and at completion—provide third-party oversight. Keep copies of permits, inspection sign-offs, warranties, and material lot numbers; these documents simplify future insurance conversations and reassure potential buyers.

Aftercare is simple but effective. Schedule roof and attic checkups twice a year, ideally spring and fall, and after major storms. Keep gutters clear and downspouts flowing to prevent water from backing up onto the roof edge. Avoid pressure washing, which can strip protective coatings and force water beneath laps. Where moss is common, gentle removal and compatible treatments help without damaging surfaces. In snowy regions, manage ice dams by improving insulation and air sealing below the roof deck rather than attacking the symptom with risky chipping from above.

Consider the economics in context. New roofs can enhance resale appeal and often recover a significant portion of costs at sale, while timely repairs protect interiors and preserve value. Energy savings from cooler roof assemblies and tuned ventilation can add quiet, ongoing returns. The real win is risk reduction: fewer emergency leaks, better indoor comfort, and documentation that stands up to scrutiny when life’s big transactions—refinancing, selling, or insuring—come around.

Before you sign, run a quick checklist:

– Verify insurance and licensing in writing

– Confirm scope in detail, including flashing and ventilation

– Understand deck repair allowances and per-sheet pricing

– Get permit and inspection responsibilities in the contract

– Align payment schedule with milestones, not just dates

– Keep all records for future reference and resale

With the right partner and a clear plan, roofing work shifts from stressful unknown to a well-managed home upgrade.