Learn about Patio Installation

Outline

– Introduction and planning fundamentals for patio installation

– Materials and design choices for a backyard patio

– Step-by-step patio installation process (DIY and professional workflows)

– How to evaluate and hire a patio installation service

– Maintenance, costs, permits, and conclusion

Introduction and Planning Fundamentals for Patio Installation

Patio installation turns open ground into a purposeful living zone, extending your home’s usable space for everyday meals, quiet reading hours, or relaxed gatherings. The appeal is practical and emotional: a stable, weather‑resistant surface brings order to your yard while setting a scene for connection. Well-planned patios also support resale value by signaling a complete, low‑maintenance outdoor lifestyle to buyers. To get there, strong planning comes first—because lasting patios begin on paper, not in a pallet of pavers.

Start by clarifying how you’ll use the space. A café table for two needs far less footprint than a grill station and a dining set for six. As a rule of thumb, allow at least 24–36 inches of circulation around seating and 36–48 inches for primary walkways. Think about sun and shade across the seasons: southern exposure may demand a pergola or umbrella, while a northern setting might benefit from lighter colors to counter cool shade. Wind patterns matter too; create shelter with low plantings or screens where breezes swirl.

Next, map out the site realities. Drainage is nonnegotiable: patios should pitch away from buildings by roughly 1–2% (about 1/8 to 1/4 inch per foot) to keep water from pooling near foundations. Soil type shapes the base depth—clay soils and freeze‑thaw climates require deeper, better‑drained foundations than sandy, well‑drained soils. If the yard is sloped, consider small retaining features or low steps rather than cutting corners on grade. Before digging, contact your local utility‑locating service to mark lines. Verify property setbacks, stormwater rules, and any homeowners’ association requirements so your plan aligns with local codes from day one.

Finally, size the budget and timeline with realistic ranges. Simple gravel or modular pavers can be installed quickly, while complex curves, inlays, or multi‑material borders extend labor and cost. A straightforward 200–300 square‑foot project often spans several days of site prep, base building, and surface installation, plus time for curing or polymeric sand to set. Upfront clarity pays off later: a measured plan, drainage strategy, and accurate material list reduce waste, prevent surprises, and lay the groundwork for a patio that looks good, drains well, and stays put.

Materials and Design Choices for a Backyard Patio

Material choice drives not only your patio’s look but its performance, maintenance, and price. Poured concrete offers a clean, continuous surface with optional color and texture finishes; unit pavers (concrete or clay) provide modular flexibility and easy repairs; natural stone delivers distinctive character and long‑term durability; and compacted gravel creates a casual, permeable surface at an approachable cost. Each option trades different strengths, so align the choice with how you’ll live on the patio and what the soil and climate demand.

Consider these broad ranges for professionally installed projects (actual figures vary by region, access, and design complexity): poured concrete roughly $8–18 per square foot; concrete or clay pavers about $12–28; natural stone approximately $20–45; compacted gravel around $6–14. Beyond price, weigh performance. Concrete is continuous, but cracks can be conspicuous; control joints and good subgrade prep limit that risk. Pavers distribute small movements through joints—individual units can be lifted and replaced if needed. Natural stone resists weathering and ages gracefully, though it’s heavier to install and often pricier. Gravel drains well and fits rustic styles, but it can migrate without stable edging and may track onto adjacent surfaces.

Texture and heat behavior matter for comfort and safety. Light, textured finishes typically stay cooler underfoot and improve slip resistance, especially in wet areas near pools or downspouts. Dark, dense stones can heat up in strong sun; consider shade solutions or lighter tones where summers are intense. For pavers, polymeric sand in the joints locks units together and helps deter weeds and ants when installed correctly. Edge restraints—steel, aluminum, or concrete curbing—keep modular systems from creeping outward under traffic and temperature swings.

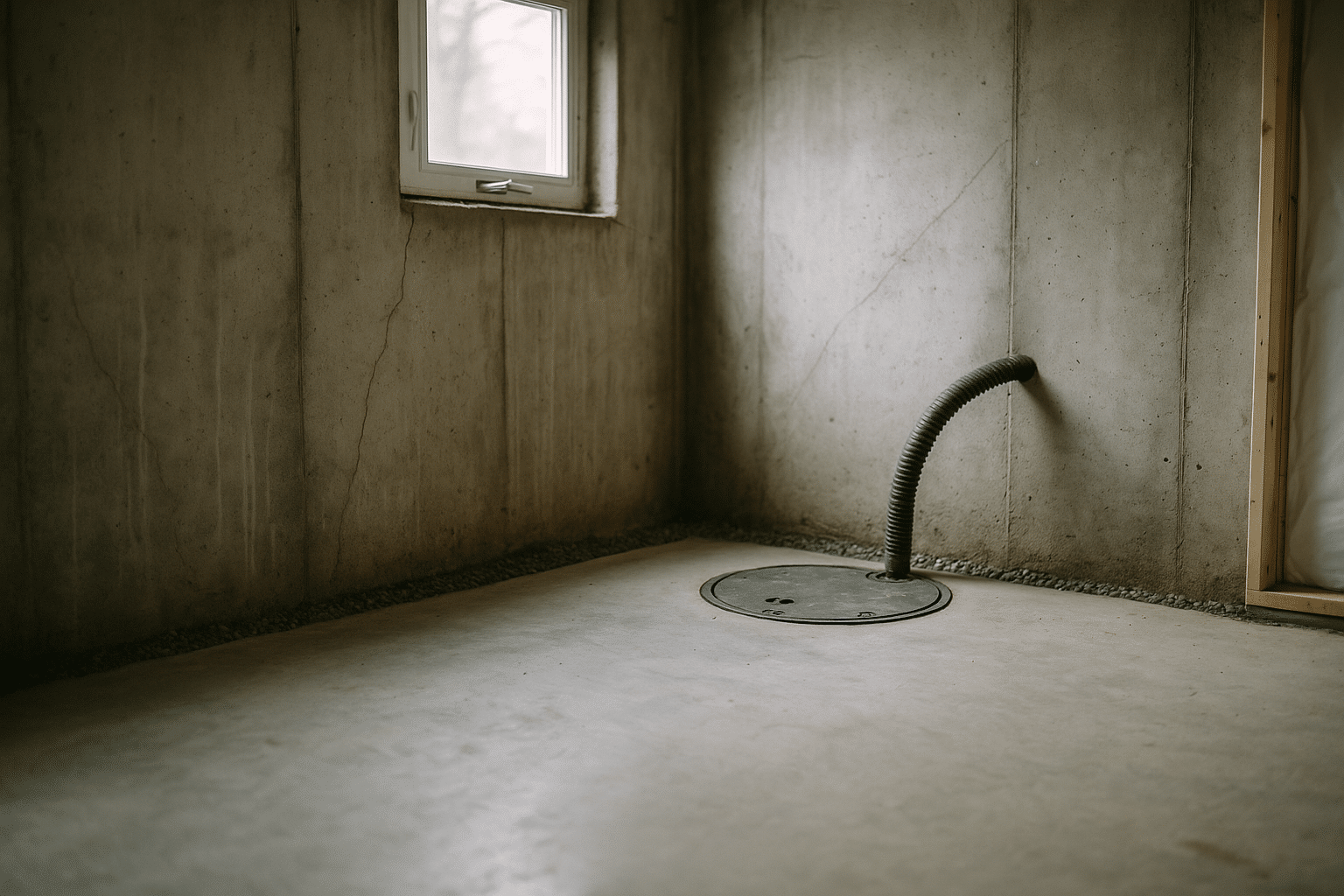

Design details influence both function and delight. Straight runs simplify installation, while sweeping curves soften a boxy yard. In dining areas, plan for a grill landing zone with a heat‑tolerant surface and fire‑safe clearance. If you like evening ambience, pre‑plan sleeves or conduits for low‑voltage lighting to avoid cutting into finished work later. Thoughtful accents—contrasting soldier courses, a small inset medallion, or a subtle color blend—can elevate the look without overwhelming the eye. Quick prompts for material alignment:

– Aim for permeable or well‑drained assemblies where stormwater rules are strict

– Choose textures that balance slip resistance with barefoot comfort

– Use edging that matches the traffic load and soil stability

– Reserve higher‑cost stone for focal borders if budget is tight

Step‑by‑Step Patio Installation Process: DIY and Professional Workflows

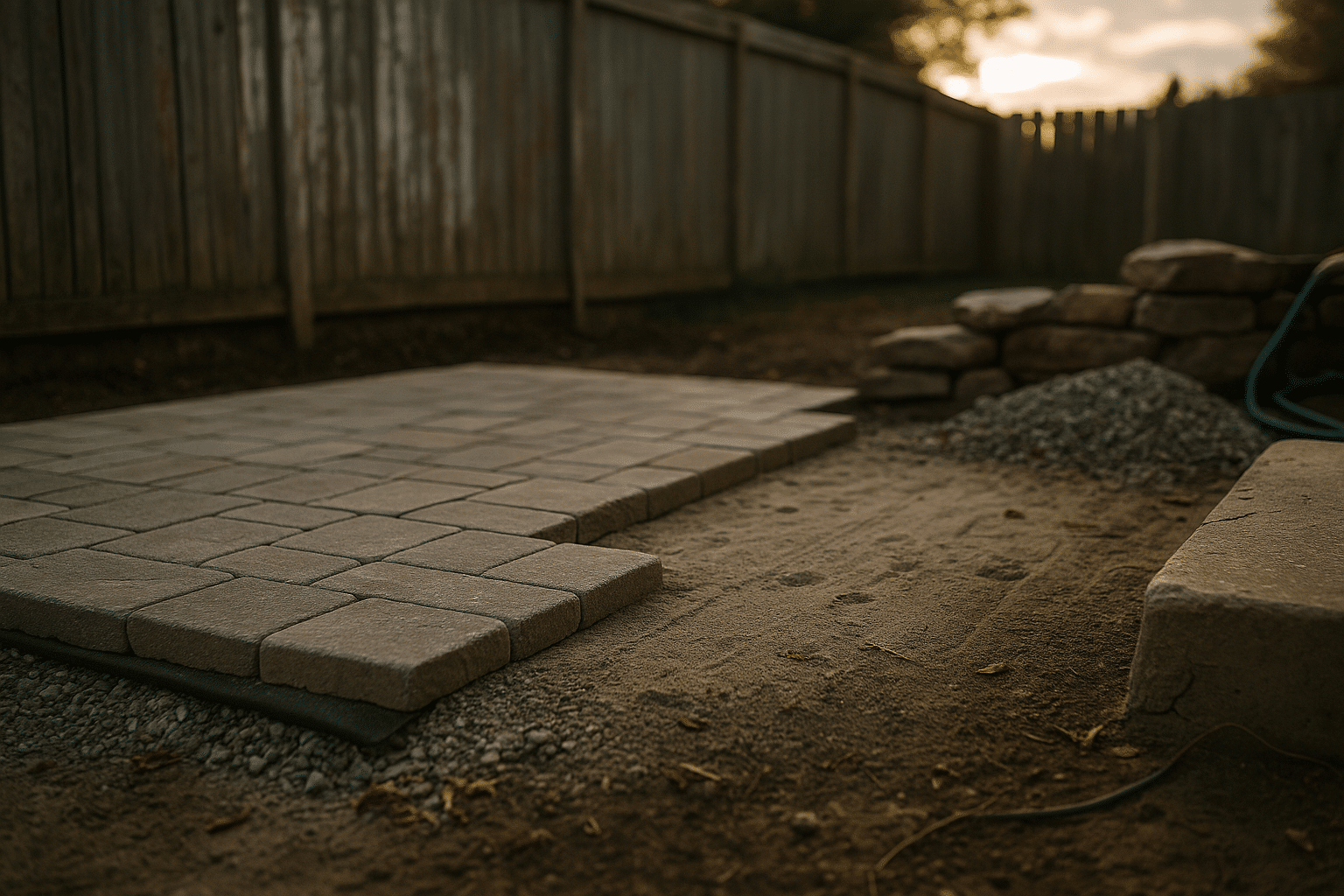

While techniques vary by material, successful patio builds follow a common sequence: assess, excavate, build a stable base, set the surface, and finish for longevity. A professional crew typically arrives with layout gear, excavation tools, compactors, and delivery schedules set; a DIYer will plan around rentals and weekend windows. Either way, the goal is a flat, well‑drained plane on a compacted foundation that resists settlement and sheds water predictably.

Layout and excavation: Establish the footprint with string lines and stakes, confirming the 1–2% pitch away from structures. Strip turf and topsoil, then excavate to accommodate the base, bedding layer, and finished surface. For many patios, a 6–8‑inch compacted aggregate base is common, increasing in colder climates or weak soils. A geotextile fabric below the base can separate fines, improving longevity on clay or mixed soils. Compact the aggregate in 2–3‑inch lifts with a plate compactor until it’s dense and unyielding underfoot.

Bedding and surface: For pavers, screed about 1 inch of sharp sand or fine chips as a bedding layer. Lay units in your pattern—running bond, herringbone, or basketweave—keeping consistent joints. Cut edges cleanly with a masonry saw or splitter, then install edge restraints. Compact the laid field with a plate compactor (using a protective mat for delicate surfaces), sweep in polymeric sand, and lightly mist to activate it per product guidance. For natural stone, set pieces on a similar bed or a small mortar bed, shimming for plane and slope. For poured concrete, build solid forms, reinforce as specified (wire mesh or rebar where appropriate), place the mix evenly, and trowel or broom to finish; cut control joints at planned intervals—often 8–12 feet—before curing.

Finishing and curing: Keep fresh concrete hydrated and protected from rapid drying; initial cure windows commonly span several days, with final strength developing over weeks. For pavers, avoid heavy furniture until polymeric sand has set; minor topping‑off may be needed after the first heavy rain. Expect a realistic timeline: a straightforward 200‑square‑foot paver patio may take 2–4 days for a crew, longer for a DIY effort paced around rentals and weather. Quality checks include:

– Uniform slope verified with a level or laser

– Solid, non‑spongy base compaction

– Tight, even joints and clean edge restraint installation

– Smooth transitions to door thresholds and lawn

DIY versus hiring comes down to time, tools, tolerance for heavy labor, and appetite for precision. Renting a compactor, saw, and screed rails narrows the cost gap but not the learning curve. A reliable installer brings speed, crew coordination, and accountability; a careful DIYer brings flexibility and cost control. Either path succeeds when the base is right and water is managed from the start.

Choosing a Patio Installation Service: What to Expect and How to Evaluate

Hiring a patio installation service can compress timelines and reduce risk, particularly for complex sites, heavy stonework, or concrete placements. The evaluation process is less about glossy photos and more about method: ask how a company handles base construction, compaction, drainage, edge restraint, joint stabilization, and expansion or control joints. The details predict longevity; vague answers predict callbacks.

Begin with credentials and clarity. Confirm licensing where required, worker’s compensation and liability insurance, and familiarity with local permitting. A well‑regarded firm will walk the site, probe soil conditions, discuss slopes and downspouts, and sketch a drainage strategy. Look for a written scope that specifies base depth, aggregate type, geotextile use, edge treatment, joint material, and finish details. An itemized proposal helps you compare apples to apples and see how changes would affect cost.

Smart questions to ask during estimates:

– How deep will you excavate, and how many compacted lifts are planned?

– What is the target slope, and how will you manage runoff?

– Which aggregate and bedding materials will you use, and why?

– How are edges restrained, and what warranty covers settlement or joint failure?

– What’s the schedule, and how are weather delays handled?

– Who pulls permits, and how are inspections scheduled?

– Can I see recent, similar projects and speak with references?

Expect a professional cadence: site visit and concept discussion; written proposal and plan; permitting (when applicable); scheduling of excavation and deliveries; base installation and inspection; surface installation; final compaction and finishing; walkthrough and care instructions. Payment schedules should align to milestones—deposit, after base installation, and upon completion—rather than heavy front‑loading. Red flags include extremely low bids without detail, reluctance to discuss drainage, skipping geotextile on marginal soils, or proposing shallow bases in freeze‑thaw regions. For peace of mind, ask to be present for key checkpoints, such as after base compaction and before final set‑in of the surface. A transparent process today means fewer surprises and sturdier edges tomorrow.

Maintenance, Costs, Permits, and Conclusion: Bringing Your Backyard Patio to Life

Patios earn their keep when they stay tidy, safe, and level across seasons. Maintenance is straightforward if you build on fundamentals. For pavers, sweep regularly and rinse as needed; top up polymeric sand every few years if joints open or after pressure washing. Consider a breathable sealer when you want enhanced color or stain resistance, but it’s optional for many systems. For concrete, gentle cleaning and periodic sealing (often every 2–3 years, depending on climate and finish) help resist stains and de‑icing salts. Natural stone varies—dense stones shrug off weather, while some porous varieties benefit from a penetrating sealer. Winter notes: use plastic shovels or broom‑style tools to avoid scratching, and select ice melt compatible with your surface.

Budgeting blends upfront and lifecycle thinking. Typical installed costs cluster roughly as follows, noting wide variation by region and complexity: gravel $6–14 per square foot, poured concrete $8–18, modular pavers $12–28, and natural stone $20–45. Curves, inlays, steps, and difficult access add labor and disposal fees. DIY approaches can trim 20–40% on labor but add tool rentals and extra time. Over the long run, unit pavers often reduce repair costs because sections can be lifted and re‑leveled; concrete repairs are possible but more conspicuous. Many homeowners report that attractive, low‑maintenance outdoor living areas can recoup a meaningful share of investment at resale—often cited in the mid‑range for curb‑appeal projects—while delivering daily value you can feel with every meal under open sky.

Permits and compliance deserve a final check. Some jurisdictions regulate lot coverage, runoff, and setbacks for impervious surfaces. Permeable systems or strategic drainage can help satisfy stormwater rules. If you’re adding gas lines, lighting, or footings for pergolas, expect additional permits and inspections. Coordinate early with local authorities and any neighborhood boards to keep the schedule on track. A documented plan with materials, slopes, and sections makes approvals smoother and keeps crews aligned in the field.

Conclusion: You don’t need a sprawling estate to craft an inviting patio—just a clear plan, the right materials for your climate and budget, and careful execution. Define how you’ll use the space, choose a surface that fits both comfort and upkeep, and commit to a properly built base with reliable drainage. If time or complexity looms large, a highly rated installation service can deliver predictable results with clear milestones and accountability. Start with a sketch and a tape measure, gather a couple of detailed quotes, and let your yard graduate from patchy lawn to a durable, welcoming room under the open sky.