Learn about HVAC Installation

Outline and Why HVAC Installation Matters

Comfort is not an accident; it is a quiet partnership between math and metal, airflow and insulation. Before we dive into tools, tonnage, and thermostats, here is the roadmap that will guide you from idea to installation without detours. This article covers five parts that build on one another like well-sealed ducts: planning, installation, air conditioning specifics, system comparisons, and a practical wrap-up with next steps. Think of this first section as the legend to your comfort map.

What we will cover and why it counts:

– Planning and scope: Load calculations, climate, and home envelope fundamentals that decide equipment size and type.

– Installation process: Duct design, electrical, condensate management, and code compliance that define safety and performance.

– Air conditioning installation: Outdoor clearances, refrigerant handling, airflow tuning, and efficiency ratings that drive summer comfort and utility bills.

– Heating and cooling systems compared: Furnaces, heat pumps, and hybrids; staging and modulation; indoor air quality features.

– Costs, timelines, incentives, and maintenance: Life-cycle thinking that keeps comfort reliable and budgets steady.

Why this matters now: In many homes, space heating and cooling account for a large slice of energy use, often approaching half of total consumption in certain climates. That means small planning choices can ripple into big monthly savings. A right-sized unit runs longer, steadier cycles, improving humidity control and indoor air quality. A carefully designed duct system trims leaks and pressure drops, minimizing the common 10–30% distribution losses seen in older or poorly sealed runs. And professional commissioning verifies the system performs as designed, which is where many projects succeed—or stumble.

Throughout the article you will also see practical comparisons and short lists that let you weigh trade-offs at a glance. If you enjoy a touch of narrative with your numbers, imagine your future system as an orchestra: equipment is the instruments, ducts are the acoustics, and commissioning is the conductor’s final rehearsal. When all three align, the result is comfort you barely notice, because the performance feels effortless. Let us outline the score, then move to the main act.

HVAC Installation Planning: Load, Ducts, Codes, and Commissioning

Solid installations begin long before a wrench turns. The first step is a room-by-room load calculation that considers square footage, insulation levels, window orientation, infiltration, internal gains, and local design temperatures. Industry-standard methods translate these factors into sensible and latent loads so equipment is neither oversized (short cycles, poor humidity control) nor undersized (long runs, poor peak performance). A right-sized system often feels quieter and steadier, because it avoids the on/off extremes that wear parts and unsettle comfort.

Ductwork design follows. The goal is to deliver the target airflow to each room within acceptable static pressure. Good practice includes sizing trunks and branches for friction rates that keep the total external static within the equipment’s rating, sealing seams with mastic, insulating ducts outside the thermal envelope, and ensuring balanced returns. Even modest leaks can push losses into double digits, especially when ducts run through hot attics or unconditioned basements. Add smooth radius elbows, short flexible runs, and tight transitions, and you will hear—rather, not hear—the difference in airflow and noise.

– Keep total external static pressure within the manufacturer’s range.

– Target 350–450 CFM per ton of cooling as a general airflow rule of thumb, adjusted for humidity goals and filtration resistance.

– Use dedicated returns where feasible to reduce room-to-room pressure imbalances.

Safety and code compliance are nonnegotiable. That means correct breaker sizing, dedicated circuits where required, properly sized condensate drains with traps and overflows, and clearances to combustibles. Exterior penetrations should be sealed to block pests and moisture, and supports must meet structural and seismic requirements where applicable. Permits provide an extra layer of quality control; inspections verify that mechanical, electrical, and condensate elements align with local codes.

Commissioning is the last mile—and too often skipped. Verifying airflow at the air handler, checking refrigerant charge via superheat and subcooling methods, measuring temperature splits under steady-state conditions, and documenting static pressure and voltage drop ensure the system operates as designed. A brief test of safety controls, defrost (for heat pumps), and thermostat operation rounds out the process. The report you receive is the installation’s receipt of performance, not just payment.

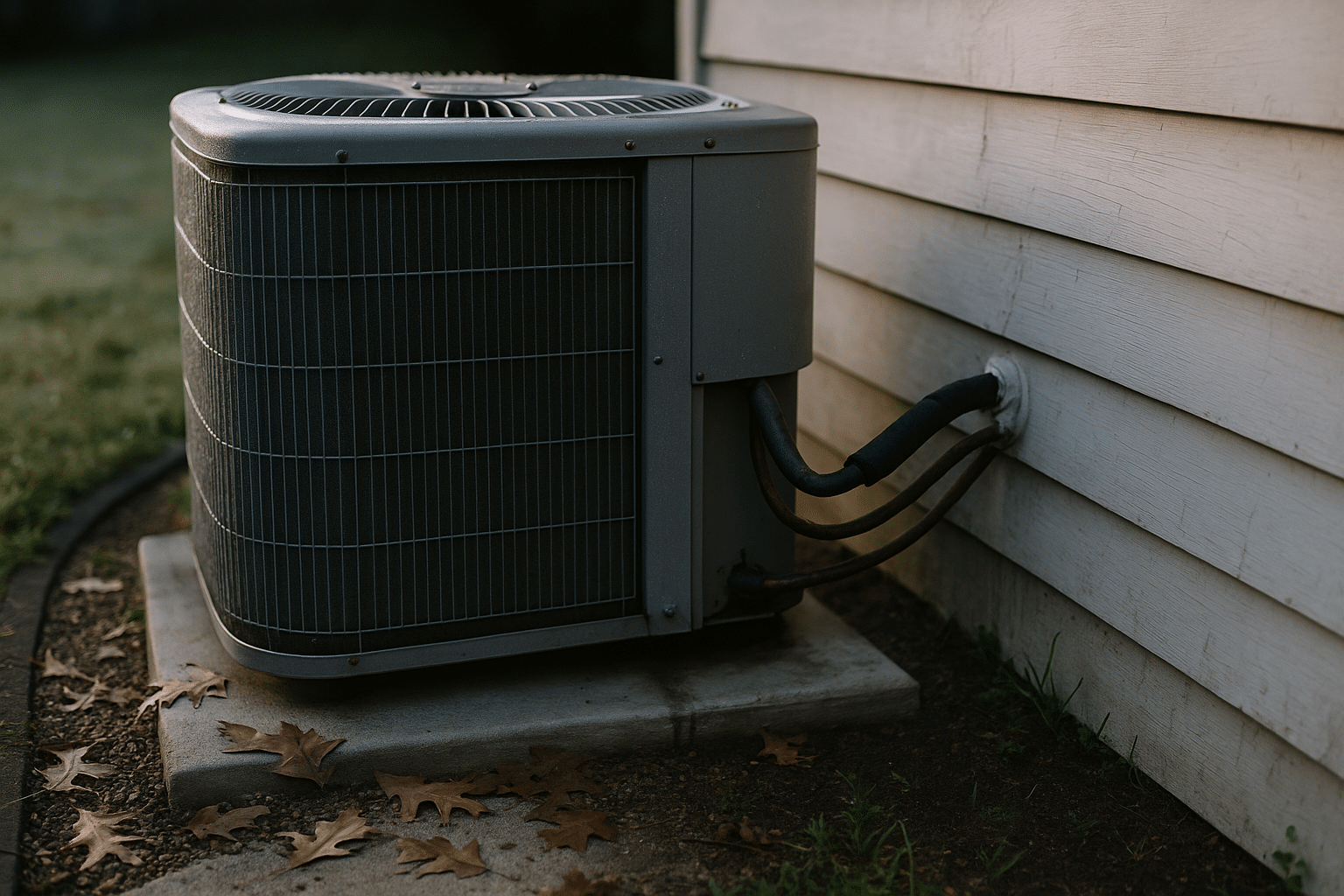

Air Conditioning Installation: From Pad Placement to Performance

Air conditioning installation weaves together outdoor placement, line set routing, indoor coil setup, and final tuning. Start outside with location and clearances: the condenser needs unobstructed airflow. Placing the unit on a level, stable pad helps prevent vibration and oil return issues. Keep shrubs trimmed and maintain side and top clearances per the unit’s data plate; crowding a condenser is like asking it to breathe through a pillow. Sun exposure can modestly affect performance, but airflow matters more than shade if ventilation is restricted.

Line sets are more than copper tubes—they are the circulatory system. Correct sizing and careful routing minimize pressure drop and oil traps. Lines should be insulated properly (especially the suction line), protected from UV where necessary, and supported at intervals to prevent kinks. Long vertical runs may need additional considerations to promote reliable oil return. Before opening refrigerant valves, technicians evacuate the system to deep vacuum levels to remove air and moisture, which otherwise form acids and degrade performance.

Indoors, the evaporator coil must be matched to the condenser and air handler. A mismatch can undercut efficiency ratings and comfort. Condensate management deserves attention: a properly trapped drain, secondary pan with float switch in attic installations, and a clean slope to the outlet prevent water stains and ceiling damage. Good filtration matters, too. Higher MERV-rated filters capture finer particles, but they also add resistance; the air handler and duct design should anticipate that pressure drop to maintain target airflow.

– Pay attention to total equivalent length of refrigerant lines; fittings add friction like hills on a highway.

– Verify blower settings to achieve the target CFM per ton, mindful of humidity goals.

– Ensure electrical disconnects and service clearances are accessible for future maintenance.

Efficiency labels translate into operating cost. Modern rating systems such as SEER2 and EER2 reflect updated test conditions closer to real-world ducted installations. While higher ratings generally reduce summer bills, two installations with the same label can perform differently if airflow or charge is off. That is why careful commissioning—temperature split, superheat/subcool checks, and confirmation of outdoor fan and compressor amperage—turns a good installation into a reliable one. In short, the craft behind the copper, not just the sticker on the cabinet, sets the tone for seasons to come.

Heating and Cooling Systems Compared: Choosing What Fits Your Home

Before picking equipment, match system type to climate, fuel availability, and comfort preferences. Traditional furnaces pair with air conditioners in many regions, delivering reliable heat through ducts and dry, toasty supply air in winter. Air-source heat pumps combine heating and cooling in one package, moving heat rather than creating it, which can translate into notable efficiency gains, especially in temperate climates. Ground-source (geothermal) systems extend that principle by drawing on stable earth temperatures, offering year-round efficiency in exchange for higher upfront complexity.

Operation style also matters. Single-stage systems are simple: full on or off. Two-stage equipment adds a gentler low stage that runs longer for improved humidity control and more stable temperatures. Variable-speed or modulating systems fine-tune output across a wide range, shaving temperature swings and often reducing noise. Pairing modulation with a variable-speed blower can improve comfort across rooms and reduce drafts. Just remember: these benefits depend on proper sizing and duct design; modulation cannot fully mask a bottlenecked return or a leaky trunk line.

Consider indoor air quality and moisture management alongside heating and cooling. Filters in the MERV 8–13 range strike a useful balance between particle capture and airflow resistance for many homes. In humid climates, dedicated dehumidification or a system configured for lower airflow in cooling mode can keep indoor relative humidity in the recommended range without overcooling. In dry regions, carefully managed humidification may improve comfort, though it must be monitored to avoid condensation in walls or windows.

– Furnaces: Familiar, fast heat; depends on fuel availability; pairs with AC.

– Air-source heat pumps: Heating and cooling in one; efficient in many climates; auxiliary heat may be needed in deep cold.

– Ground-source systems: High efficiency and steady comfort; higher upfront cost and site work.

– Ductless systems: Flexible zoning and no ducts to lose energy; wall or ceiling units change room aesthetics.

Compatibility and future plans should influence the choice. If you expect to improve insulation or windows soon, size for the upgraded envelope rather than today’s draftier reality. If you value room-by-room control, zoning with dampers or ductless heads can target problem areas without overhauling the entire system. If resilience is a priority, consider how your system behaves during outages or extreme weather, and whether backup heat sources or surge protection make sense. The right system is the one that fits your home’s physics and your family’s routines, not just the nameplate tonnage.

Conclusion and Next Steps: A Clear Path to Lasting Comfort

By now, the mystery behind HVAC installation should feel more like a method: measure, design, install, and verify. Whether you are replacing a tired unit or outfitting a new space, a few disciplined steps protect comfort and budget alike. Start with a thorough load calculation and a duct assessment; these two tasks shape equipment selection more than any catalog. Insist on documented commissioning so your new system’s performance is proven, not assumed. Then commit to simple maintenance that keeps efficiency steady and surprises rare.

Use this quick action list as you plan:

– Ask for a room-by-room load report, not a rule-of-thumb estimate.

– Request a duct evaluation with measured static pressure and leakage notes.

– Get a written scope detailing breaker sizes, line set routing, condensate safeguards, and clearances.

– Confirm matched equipment ratings and that airflow targets will be set and recorded.

– Collect a commissioning report with temperature split, superheat/subcool, static pressure, and airflow values.

– Schedule filter changes (often every 1–3 months), coil cleanings, and a yearly check-up.

– Track utility bills after install; stable or lower usage at similar weather points to a healthy system.

Budget with life-cycle costs in mind. Upfront prices are visible, but energy, maintenance, and comfort have long tails. Efficiency upgrades, duct sealing, and smart controls often pay back through quieter operation, steadier humidity, and lower bills. Incentives from local utilities or governments can ease the step into higher-efficiency gear or envelope improvements; a quick eligibility check is worth the call. If you plan to add solar, renovate, or change occupancy patterns, mention it now—today’s design can anticipate tomorrow’s home.

Finally, trust the process. Good HVAC work looks unremarkable once finished: rooms reach setpoint, air sounds calm, and the thermostat hardly needs attention. That calm is the product of careful planning, precise installation, and honest verification. Follow the path outlined here, and you will trade guesswork for clarity and seasonal discomfort for year-round ease—an investment measured not just in energy savings, but in the everyday quiet of a home that simply feels right.