Learn about Engine Diagnostic Service

Outline

1. The role and basics of engine diagnostics

2. Car-specific nuances: OBD-II, drivability data, and freeze-frame insights

3. The check engine light: common codes, symptoms, and root causes

4. What happens during an engine check service: workflow, tools, and pricing

5. Prevention and decision-making: a practical conclusion

Engine Diagnostics 101: What It Is and Why It Matters

Outline of this article:

– Foundations: how modern diagnostics translate sensor data into clear answers

– Practical differences in car engine diagnostic versus generic engine testing

– Check engine light demystified: what codes really signal

– Inside a professional engine check service: steps, tools, time, and price

– Preventive strategy and confident decision-making

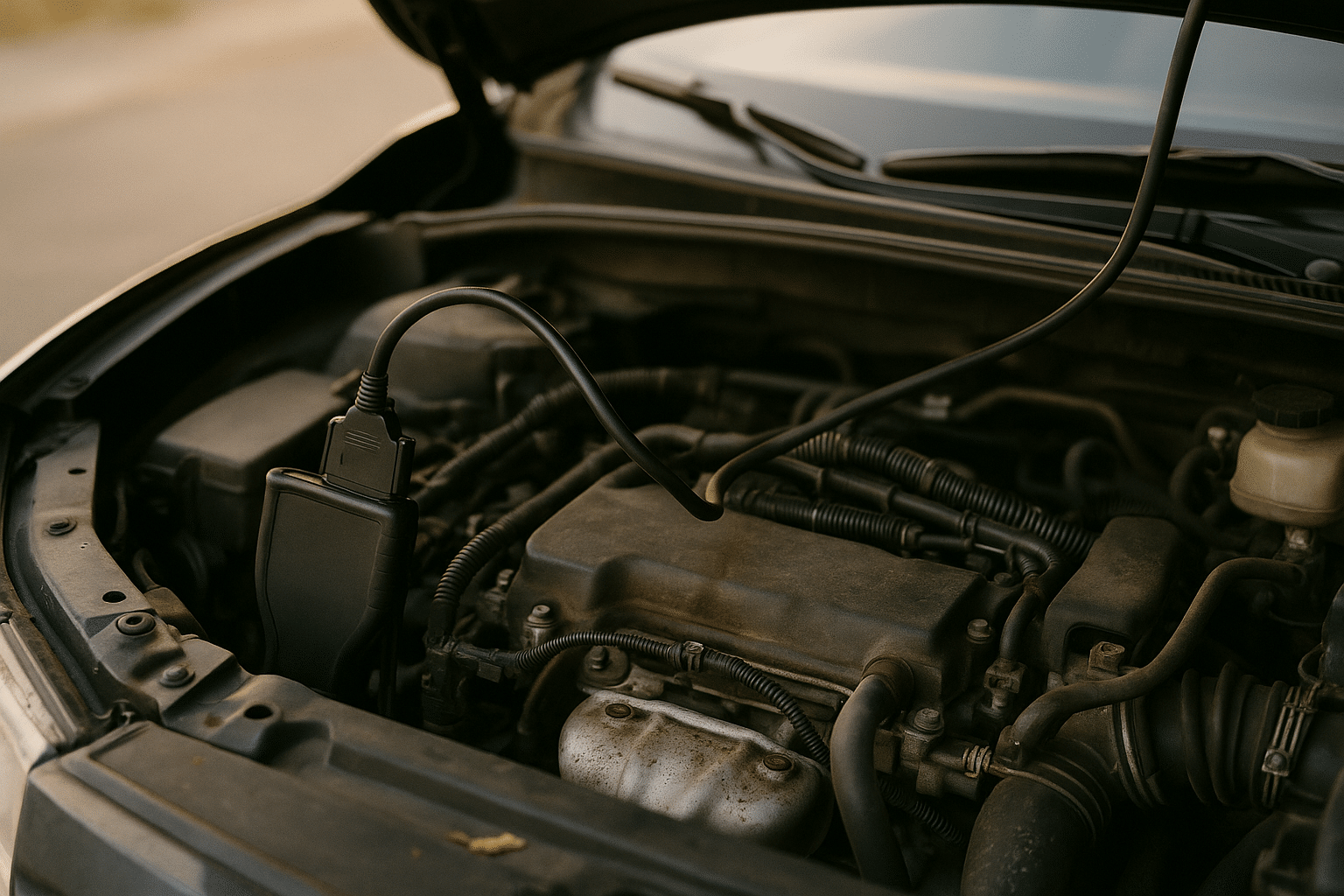

Every modern engine is a storyteller, and diagnostics is the listening skill that turns scattered clues into a coherent plot. At its core, engine diagnostics means collecting data from sensors and control modules, interpreting that information, and confirming the root cause through targeted tests. In passenger vehicles sold in many markets since the mid-1990s, the On-Board Diagnostics (often called OBD-II) standard supplies a shared language of Diagnostic Trouble Codes (DTCs), live data streams, and readiness checks. These resources are invaluable, but they are only the beginning. Accurate diagnosis still hinges on method: interview, inspect, measure, verify.

Consider the sheer number of data points available during a scan. A technician can monitor oxygen sensor voltage swings, short- and long-term fuel trims, mass airflow readings, throttle angle, coolant temperature, and misfire counters, all while the engine idles or is driven on a route that triggers symptoms. Freeze-frame data records a snapshot of conditions at the moment a fault set, offering a time capsule of RPM, load, and temperature. With that context, a code like “system too lean” stops being a riddle and becomes a map pointing toward air leaks, metering errors, or fuel delivery issues.

Why it matters goes beyond clearing a light. A methodical diagnostic prevents the “parts cannon” approach—replacing components in hopes of luck—saving both money and frustration. It can also reduce emissions, protect catalytic converters, and prevent failures that strand drivers at inconvenient moments. In real-world terms, this looks like catching a small vacuum leak before it drifts fuel trims, overheats the catalyst, and snowballs into a multi-thousand-dollar repair.

Think of diagnostics as science applied to a machine in motion: you form a hypothesis, test it with instruments, and confirm or disprove it with repeatable results. The engine, for its part, always tells the truth in data. Our job is to ask the right questions.

Car Engine Diagnostic in Practice: Sensors, Data, and Test Drives

Automotive engines live in a unique ecosystem where electronics, emissions strategy, and drivability standards converge. Car engine diagnostic practice aligns with OBD-II protocols but extends further into how the vehicle behaves in traffic, during cold starts, and under load. Real progress usually begins with a structured approach: verify the customer’s concern, perform a visual inspection, scan for codes, examine freeze-frame context, watch live data, and run pinpoint tests that prove a cause instead of guessing at it.

Under the hood, key sensors and systems shape the story:

– Air metering: mass airflow or manifold pressure sensors define how much air enters the engine

– Fuel control: injector pulse, fuel pressure, and pump performance determine delivery

– Exhaust feedback: oxygen and wideband sensors steer closed-loop adjustments

– Ignition timing: crank and cam sensors synchronize spark and fuel

– Emissions systems: evaporative controls, EGR strategies, and catalyst efficiency checks manage pollutants

During a scan, a seasoned eye looks at trends, not just snapshots. Fuel trims hovering near zero suggest equilibrium; trims drifting positive imply a lean condition, potentially from unmetered air, low fuel pressure, or exhaust leaks ahead of oxygen sensors. Misfire data—especially cylinder-specific counters—points toward spark, compression, or injector issues. If misfires worsen under load, ignition coils or fuel delivery are suspects; if they spike at idle, vacuum leaks or valve sealing may be in play. This is where a controlled road test matters: duplicating the symptom under safe, repeatable conditions so that live data can confirm the theory.

Confirmatory tests minimize doubt:

– Smoke testing locates vacuum and EVAP leaks invisible to the eye

– Fuel pressure and volume tests separate weak pumps from clogged filters or regulators

– Compression and leak-down tests assess mechanical health

– Oscilloscope waveforms reveal sensor dropouts too fast for scanners to catch

Hybrid and start-stop systems add layers—from high-voltage management to engine restarts at traffic lights—making battery health and network communication checks part of the routine. Regardless of platform, the discipline stays the same: observe, measure, and only then replace. When applied consistently, car engine diagnostic practice transforms dim dashboard hints into confident, verified repairs.

The Check Engine Light Explained: Codes, Symptoms, and Next Steps

The check engine light is a messenger, not a verdict. It illuminates when the control module detects conditions outside expected parameters, often after a fault occurs across multiple drive cycles. Codes fall into families—Powertrain (P), Body (B), Chassis (C), and Network (U)—with P-codes being the typical concern for engine and transmission behavior. Many vehicles store freeze-frame data at the first occurrence, capturing RPM, load, and coolant temperature so you can reconstruct the moment the light appeared.

Common themes and examples help orient your response:

– Misfire (e.g., random misfire): symptoms include rough idle, hesitation, and possible catalyst damage if ignored

– System too lean: may stem from intake leaks, low fuel pressure, or metering sensor drift

– Catalyst efficiency below threshold: could indicate converter wear, misfires upstream, or oxygen sensor issues

– EVAP leak detected: often linked to loose caps, cracked hoses, or failed valves

Severity varies. A flashing light typically warns of an active misfire that can overheat the catalytic converter; reduce load and address immediately. A steady light often signals conditions that affect emissions and fuel economy but may allow short trips. The most important step is restraint: avoid clearing codes before capturing freeze-frame and pending data, as that evidence is your compass.

Next steps, simplified:

– Verify the complaint and note operating conditions when symptoms occur

– Scan for codes and pending faults; record freeze-frame data

– Check related systems visually (loose connectors, damaged vacuum lines, oil contamination)

– Use live data to compare sensor readings to expected ranges

– Confirm with targeted tests (smoke, fuel pressure, compression, or electrical checks)

One myth deserves retiring: a code does not automatically equal a part. A lean code doesn’t always mean a sensor replacement; it might be telling you unmetered air is sneaking in or that fuel delivery is marginal. By interpreting codes in context—with trims, temperatures, and loads—you convert a generic warning into a precise repair plan. That translation keeps costs in check and reliability high.

Inside an Engine Check Service: Workflow, Tools, and Costs

An engine check service is a structured evaluation designed to move from symptom to verified cause with minimal waste. Although shops vary, the core workflow is consistent and transparent when done well. Expect a brief interview to capture the complaint, a visual inspection to catch obvious issues, a scan of the control module for codes and freeze-frame data, a review of live parameters, and targeted testing that proves the fault beyond doubt. The aim is evidence, not hunches.

Typical sequence you may encounter:

– Intake and road test: gather the story, then reproduce the symptom safely

– Code and data review: note DTCs, pending codes, readiness monitors, and freeze-frame

– Visual and basic checks: intake boots, vacuum lines, harnesses, grounds, oil and coolant condition

– Live data analysis: trims, sensor voltages, commanded vs. actual values

– Pinpoint tests: smoke test, fuel pressure/volume, compression and leak-down, circuit loading, or oscilloscope traces

– Verification: clear codes, perform a drive cycle, and confirm the fix holds

Tools span from simple to sophisticated. Scanners read codes and graph data; multimeters and test lights validate voltage and ground integrity; oscilloscopes capture fast sensor events; smoke machines reveal leaks; pressure gauges quantify fuel and compression; infrared thermometers help judge catalyst activity. None of these tools work without a method, and a method is only as good as the documentation it produces. Quality services typically end with a written report summarizing findings, test results, and recommendations in plain language.

Time and cost depend on complexity. A basic evaluation may take 30–60 minutes, while intermittent faults or multiple overlapping issues can require several hours across multiple visits to capture conditions. Many shops bill diagnostic time in fractions of an hour at standard labor rates that vary by region and vehicle complexity. Clarify up front what is included, how updates are communicated, and at what decision points authorization is needed. The value of a thorough engine check service lies in reducing rework, avoiding unnecessary parts, and restoring confidence that the root cause—not just the symptom—has been resolved.

Conclusion: From Warning Light to Confident Maintenance Decisions

Whether you are a daily commuter, a fleet coordinator, or a careful used-car shopper, a clear diagnostic process turns uncertainty into a plan. Your dashboard light is an invitation to investigate before issues escalate, not a sentence handed down without appeal. With standardized codes, freeze-frame snapshots, and live data at hand, a disciplined workflow—interview, inspect, measure, verify—delivers outcomes you can trust. That trust matters when you are weighing repair options, timing maintenance, or budgeting for the year ahead.

Use this checklist to stay proactive:

– Capture the symptom’s context: temperature, speed, fuel level, and recent work

– Record codes and freeze-frame before clearing anything

– Compare data to expectations, not guesses

– Confirm with one or two decisive tests

– Verify the fix and keep a copy of the report for future reference

The same principles guide both simple and complex cases. A small intake leak caught early protects the catalyst and preserves fuel economy. A stubborn intermittent misfire solved through scope work and road testing restores smoothness without gambling on parts. Over time, that precision prevents breakdowns, reduces emissions output, and helps the engine age gracefully.

If you prefer to handle basics yourself, a consumer-grade scanner and a methodical mindset can surface patterns worth sharing with a professional. When the fault is intermittent, safety critical, or intertwined with multiple systems, partnering with an experienced technician pays off through efficiency and documentation. Either way, lean on data, respect the process, and let evidence lead. Your engine already speaks; diagnostics makes the translation actionable—and your decisions steadily more confident.